In the world of coatings, formulators often struggle with recurring challenges: films that peel or lose adhesion too quickly, poor resistance against harsh chemicals, and curing times that slow down production. These problems often trace back to one key issue which is insufficient cross-linking within the coating matrix, which leaves the final product weaker and less durable than required for demanding industrial applications.

Introducing PUREti AL

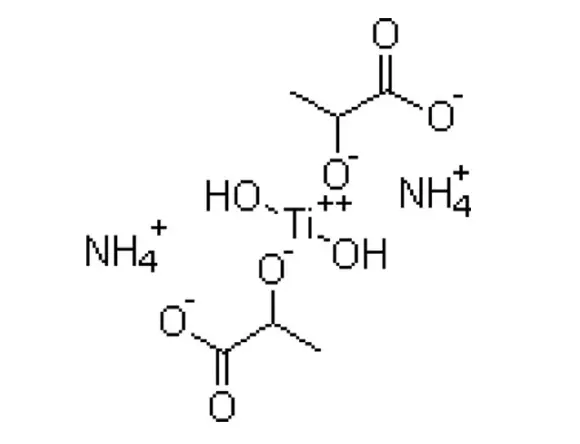

PUREti AL from Polygel is a titanium ammonium lactate solution that is specifically designed as a catalyst and cross-linking agent to enhance coating formulations. By accelerating chemical reactions and strengthening polymer bonds, PUREti AL enables the creation of coatings that cure more efficiently and deliver superior performance over time.

Key Benefits of PUREti AL

Superior Adhesion and Cross-Linking

One of the key strengths of PUREti AL is its ability to improve adhesion between coatings and substrates through more efficient cross-linking. Research on titanium lactate compounds has demonstrated that when applied to polymeric surfaces, these chelates form thin titanium dioxide layers that act as strong bonding interfaces. This additional bonding layer enhances the grip of the coating, significantly reducing risks of peeling, blistering, or delamination that often occur in harsh conditions. With PUREti AL incorporated into the formulation, coatings achieve a tighter molecular network and stronger adhesion to the substrate, ensuring better long-term reliability and performance.

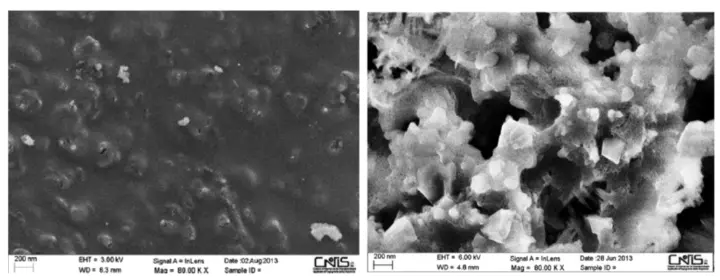

Scanning electron micrographs of titanium oxide (left) and lithium iron phosphate (right).

Improved Durability and Hardness

Another proven benefit of PUREti AL is the improvement in durability and surface hardness. Titanium lactate precursors generate anatase TiO₂ structures with excellent mechanical properties. These structures increase the hardness of the coating layer, making it more resistant to daily wear and tear such as impacts, abrasion, and surface pressure. This added durability means that coatings not only last longer but also maintain their protective qualities for extended periods, reducing maintenance needs and costs. For industrial and outdoor applications where coatings are exposed to constant mechanical stress, this advantage is particularly valuable.

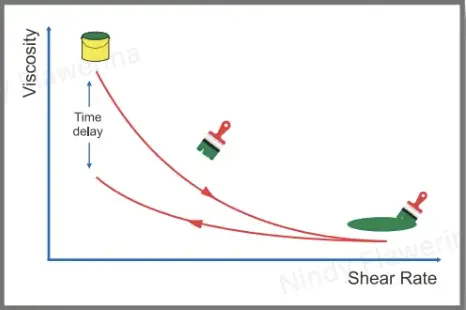

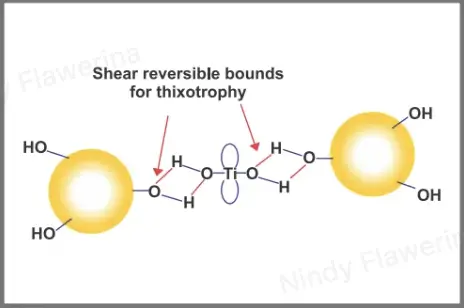

Rheology Modifier: Thixotrophy

When PUREti titanates are added, they create a gel-like network within colloid-stabilized paints. The image shows how the paint consistency changes: on the left, without any additives, the material spreads out, while moving to the right, increasing additive concentration builds a stronger gel structure. This is the principle used in producing non-drip paints.

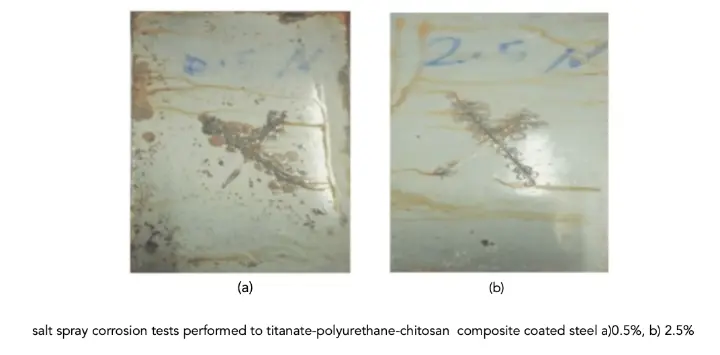

Anti-corrosive coatings crosslinking

PUREti titanates provide a revolutionary, non-toxic alternative for achieving superior passivation performance, offering a solution for industries to completely replace toxic corrosion inhibitors like Cr(IV) or CR(III) compounds. The core technology involves applying a baking process to fastener coatings, which facilitates the formation of a hybrid titanium rich micro-segregated layer on the surface. Furthermore, these titanates are not limited to zinc-rich primers; their water-based thin-layer form is also crucial for providing temporary corrosion protection to steel coils during manufacturing and transport.

Secure Your Coating Performance with PUREti AL

If your company struggles with the recurrent challenges of films that peel or lose adhesion, poor resistance against harsh chemicals, or slow curing times that bottleneck production, then you need a foundational chemical solution. We strongly recommend incorporating PUREti AL to solve these issues. By deploying its superior capacity as a cross-linking agent and catalyst, PUREti AL ensures the formation of a durable, tightly-bonded coating matrix, delivering the superior performance required for demanding industrial applications.

In addition to its applications in coatings, PUREti AL is widely recognized as an effective adhesion promoter for water-based printing ink formulations. At Maha, we carry the entire PUREti portfolio from Polygel, covering all coatings and printing ink applications for Thailand and Vietnam markets. Our comprehensive range allows customers to select the most suitable PUREti solution for their specific process needs, delivering consistent performance and reliable results.

Contact Maha today to request a sample and transform your formulation durability!