Why Epoxy Systems Need Curing Agents?

Epoxy resins are widely used across industries because of their exceptional adhesion, durability, and resistance to chemicals. However, epoxy resin alone cannot cure into a solid material—it requires a curing agent (often referred to as a hardener) to initiate the chemical reaction that transforms liquid resin into a strong thermoset.

Among the available types, amine curing agents are among the most common. They provide reliable reactivity, excellent adhesion, and resistance to a wide range of environmental conditions. For applications requiring easy processing, a low-viscosity curing agent ensures smooth mixing and substrate penetration.

About Epamine PC-17

Epamine PC 17 is a specialised aliphatic amine curing agent designed for epoxy resin systems. Known for its very low viscosity, this curing agent enables excellent flow and penetration, making it ideal for applications such as injection grouts and consolidating mortars.

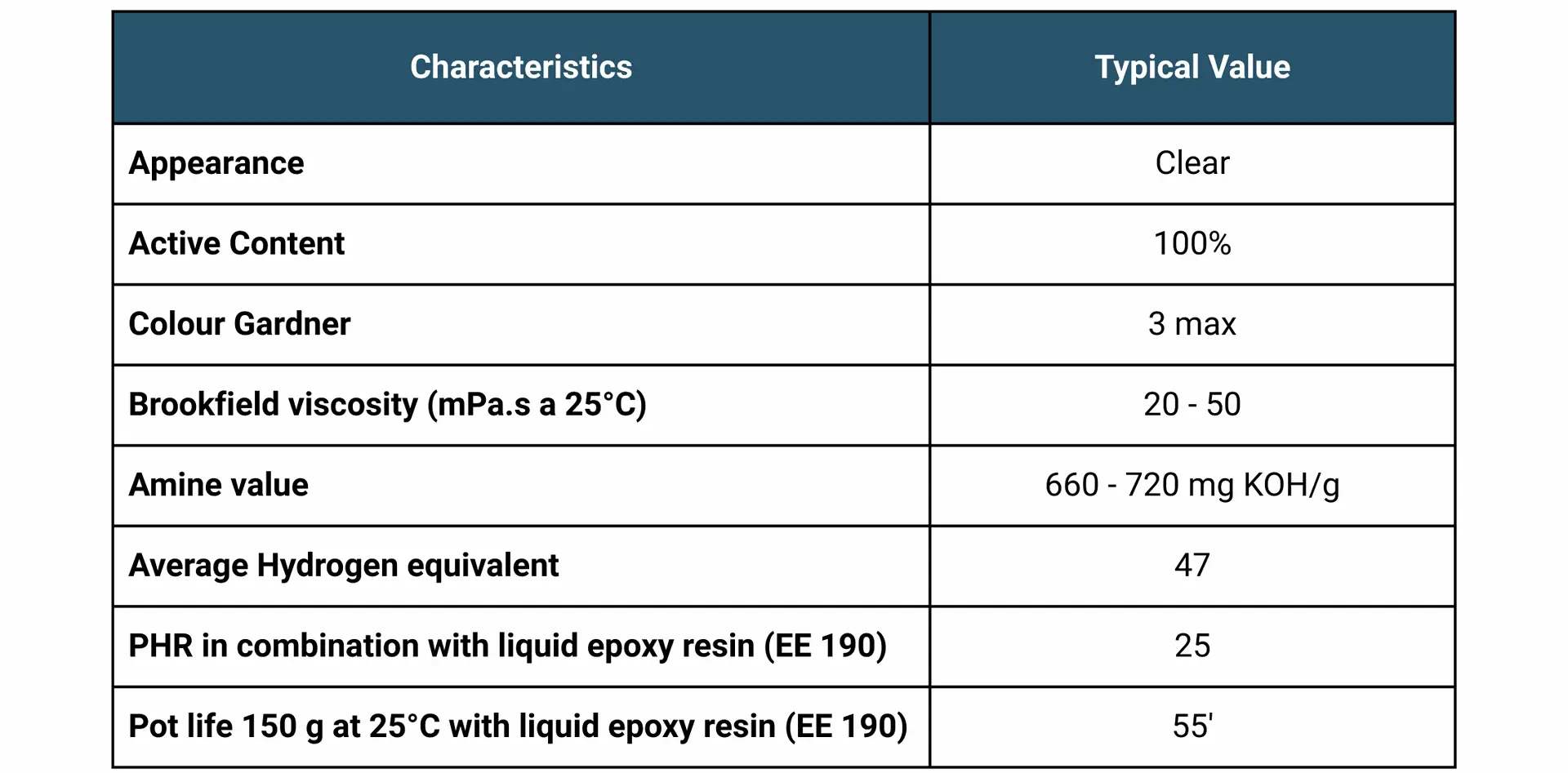

Ảnh 1. Epinephrine PC 17 Characteristics

Key highlights of Epamine PC-17

- Type: Aliphatic amine

- Form: Clear, low-viscosity liquid

- Function: Epoxy resin hardener

- Benefit: Ensures outstanding mechanical performance and reliable chemical resistance

With these properties, Epamine PC-17 stands out as an epoxy hardener that balances ease of application with strong performance.

How Epamine PC-17 Works as an Amine Hardener for Epoxy

When mixed with liquid epoxy resin, Epamine PC 17 reacts as an amine hardener for epoxy, crosslinking the resin chains to form a three-dimensional network. This curing process:

- Provides high mechanical strength

- Ensures durability and chemical resistance

- Delivers a controlled pot life for practical working times

As a low viscosity curing agent, Epamine PC 17 allows efficient wetting of substrates and fillers, ensuring thorough consolidation even in dense materials like concrete or stone.

Key Applications of Epamine PC-17

Because of its unique properties, Epamine PC-17 finds use in a variety of epoxy-based systems:

- Construction: Injection grouts, consolidating mortars, and crack repair

- Industrial coatings: Enhance adhesion and resistance in protective layers

- Adhesives: Provides durable bonding across metals, composites, and stone

- Composites: Reinforces mechanical performance in fibre-reinforced epoxy systems

Image 2. Epamine PC 17 Application Examples

In all these cases, Epamine PC-17 serves as a reliable epoxy resin hardener only, ensuring that systems perform under demanding conditions.

Epamine PC-17 Handling Guidelines

Like most amine curing agents, Epamine PC-17 requires proper handling to maintain performance and user safety:

- Storage: Keep in dry, closed containers between 5–35 °C.

- Shelf Life: Stable for up to 18 months when stored correctly.

- Safety: Use gloves, goggles, and protective clothing. Avoid inhalation of vapours.

- Preparation: Mix epoxy resin and curing agent immediately before application for best results.

Where to Buy: Your Trusted Epamine PC-17 Supplier

Finding the right curing agent supplier is critical for ensuring product quality and technical support. Maha offers Epamine PC-17 along with expert guidance on application, safe handling, and optimisation of epoxy systems.

Contact our team today to request FREE samples or technical assistance, and discover how Epamine PC-17 can deliver reliable performance in your epoxy formulations!