Why Are Marine Coatings Prone to Corrosion?

The marine environment is among the most aggressive for metal structures. Constant exposure to saltwater, oxygen, humidity, and temperature fluctuations accelerates oxidation and coating degradation. Over time, these conditions compromise the protective layer and make ships, offshore platforms, and steel structures highly vulnerable to rapid and severe corrosion.

Corrosion not only damages the appearance of a vessel or structure but also brings serious consequences:

- Reduced structural strength leading to safety risks.

- Higher maintenance and repair costs due to frequent repainting or part replacement.

- Downtime in operations affects productivity and profitability

👉 In short, corrosion is more than just a surface problem. It directly impacts the performance, safety, and lifecycle of marine assets.

What Are Common Methods to Prevent Corrosion in Marine Environments?

Over the years, industries have developed several approaches to combat corrosion in marine environments:

Protective coatings (epoxy, polyurethane, alkyd)

It acts as a barrier to shield steel from water, oxygen, and salts.

Cathodic protection (zinc, aluminium, magnesium anodes or impressed current systems)

Utilising sacrificial anodes (zinc, aluminium, or magnesium) or impressed current cathodic protection (ICCP) systems to prevent metal corrosion.

Material Selection

Using corrosion-resistant alloys (stainless steel, composites), though often costly.

Corrosion Inhibitors

Chemical additives in coatings that slow or block reactions at the metal surface.

What Is Zinc Phosphate and How Does It Protect Steel?

Zinc phosphate (Zn₃(PO₄)₂) is a widely used anticorrosive pigment in modern coatings. Unlike chrome-based pigments, it is chrome-free and environmentally safe, offering protection through two mechanisms:

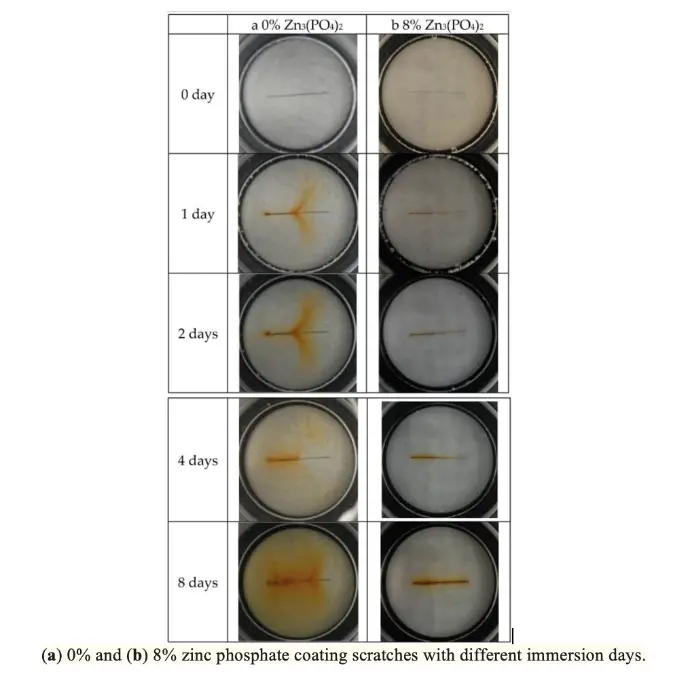

- Barrier protection – forms a dense layer that slows penetration of corrosive agents.

- Chemical passivation – reacts with steel to form a stable protective phosphate film, reducing oxidation.

This dual action makes zinc phosphate a trusted choice in marine coatings, combining effectiveness with compliance with today’s strict environmental standards.

Why Choose Zinc Phosphate in Marine Coatings?

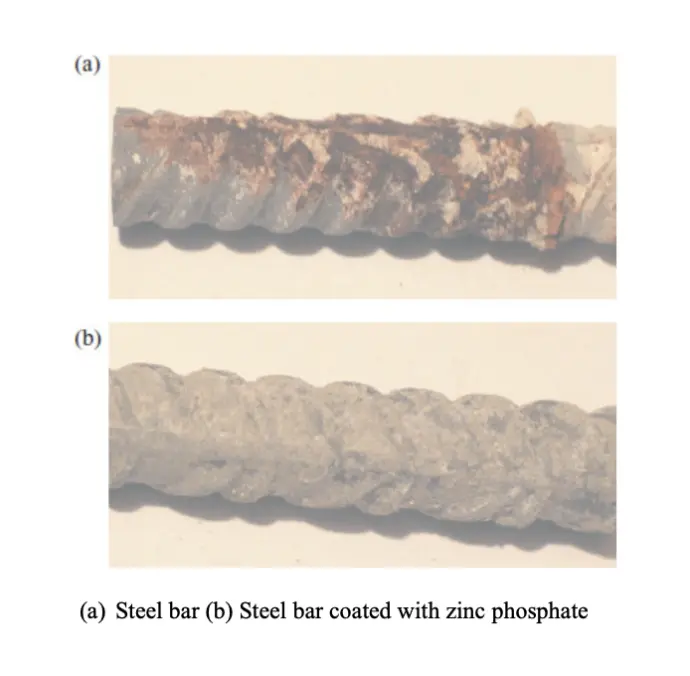

Excellent corrosion resistance, proven in laboratory and field testing.

Zinc phosphate protects metals through a dual mechanism: it acts as a physical barrier and chemically forms a stable phosphate film that slows corrosion.

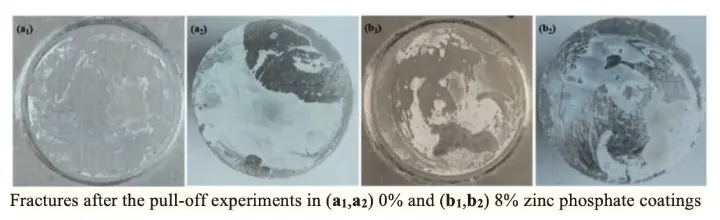

Strong adhesion for subsequent paint layers, improving coating durability.

The crystalline layer formed during zinc phosphate treatment creates a micro-rough surface. This enhances primer and topcoat adhesion, reducing risks of peeling, blistering, or underfilm corrosion.

Durability and cost efficiency, reducing the need for frequent recoating.

By slowing the rate of corrosion and extending coating lifetime, zinc phosphate helps reduce maintenance frequency and repair costs for marine structures.

Compared to alternatives like corrosion-resistant alloys, zinc phosphate coatings represent a cost-effective, high-performance solution

Environmentally friendly, free from toxic heavy metals like lead and chromium.

Unlike older anticorrosive pigments based on chromium or lead, zinc phosphate offers strong performance without toxic heavy metals. It complies with environmental regulations such as REACH (EU) and EPA (US), making it safer for both workers and the environment.

Zinc Phosphate Supplier from Maha Asia

At Maha Asia, we provide a reliable selection of zinc phosphate pigments to meet different industrial needs:

Zinc Phosphate 409-2

General-purpose grade for anticorrosion paints in containers, steel, and electronic materials.

Zinc Phosphate 409-3

Higher whiteness, controlled impurities, ideal for marine and steel structures.

Zinc Phosphate 409-4

High-purity, low heavy-metal content, designed for advanced antirust coatings.

Each grade balances performance, safety, and cost-efficiency, giving flexibility for specific applications. Discover how Maha Asia can strengthen your marine coatings!

Empower Your Marine Coatings with Maha Asia!

Contact the Maha Asia technical team today for in-depth consultation, free testing samples, and discover how Zinc Phosphate can:

- Dramatically enhance corrosion resistance

- Extend the service life of your coatings

- Optimise maintenance costs for your marine assets