Microbial contamination is one of the biggest threats to waterborne coatings, paints, adhesives, and emulsions. Without reliable in-can preservatives, entire batches risk spoilage — leading to production losses, recalls, and customer dissatisfaction. At the same time, regulations are tightening, limiting the use of formaldehyde donors, MIT, and CIT. This makes the need for a formaldehyde-free preservative more urgent than ever. Choosing the right solution ensures both wet state protection and long-term compliance for formulators, R&D teams, and business owners.

Key Benefits of In-Can Preservatives for Waterborne Systems

In-can preservatives, sometimes called wet state preservatives, provide the first line of defense against microbial spoilage in paints and other waterborne systems. By preventing contamination inside the container, in-can preservatives, also known as biocides, protect both product integrity and profitability.

The right in-can preservative biocide offers:

- Broad-spectrum efficacy against bacteria, mold, and yeast.

- Compatibility with waterborne formulations like coatings, adhesives, emulsions, and dispersions.

- Low use levels, making them a cost-effective solution.

- Compliance with modern standards, supporting formulators and R&D teams in meeting customer and regulatory expectations.

In short, an effective in-can preservative reduces risk, extends shelf life, and safeguards your product portfolio.

Biocide in Water Treatment

The value of a reliable paint biocide extends well beyond paints, with applications in many different industries:

Coatings and Paints

Image 1. Paint & coating

Protecting latex paints, polymer emulsions, and dispersions from microbial attack, ensuring long-term product stability and customer satisfaction.

Adhesives and Sealants

Image 2. Adhesives & sealant

Keeping formulations stable during extended storage periods, reducing the risk of spoilage and production downtime.

Pigment and Mineral Slurries

Image 3. Water splash with pigment powder

Preventing bacterial and fungal growth in high-solid systems, maintaining consistent quality and performance.

Household, Industrial, and Institutional (HI&I) Products

Image 4. Household products & surface sanitizer spray

Supporting hygiene and cleaning applications where stability and reliability are essential to product safety and brand trust.

How SURFSHIELD LS Works

SURFSHIELD LS is a next-generation in-can preservative biocide for modern waterborne formulations. It uses a synergistic blend of BIT (1,2-benzisothiazolin-3-one) and sodium pyrithione to interrupt microbial growth, preventing bacteria, mold, and yeast from spreading in coatings, paints, adhesives, and emulsions. Unlike traditional preservatives, it achieves broad-spectrum protection without relying on formaldehyde, MIT, or CIT—making it a safe and compliant choice for today’s regulatory environment.

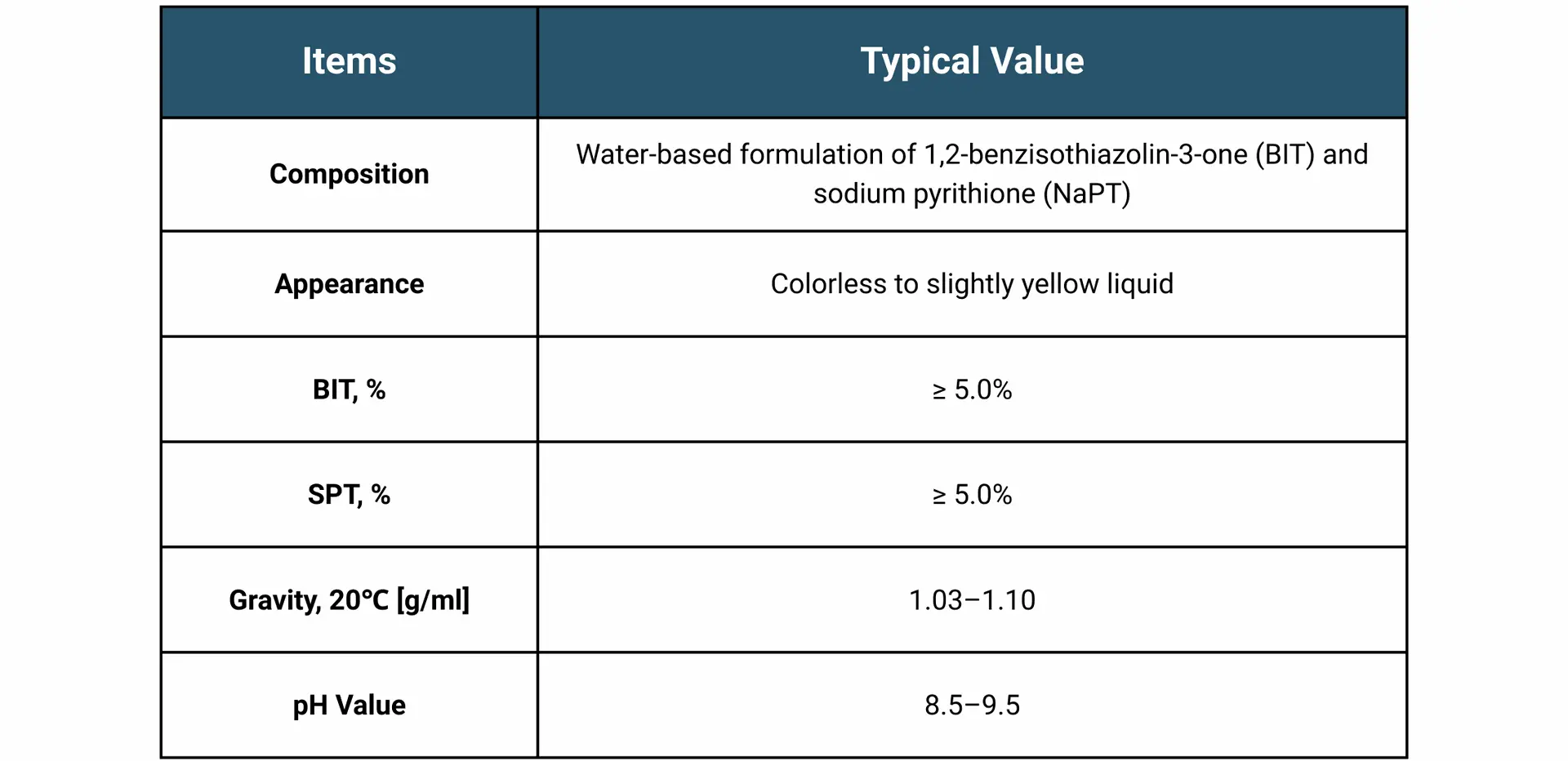

To support consistent formulation, SURFSHIELD LS offers the following typical properties:

Image 1. SURFSHIELD LS Typical Properties

Whether used as a coating or paint preservative, an adhesive biocide, or a polymer emulsion safeguard, SURFSHIELD LS offers broad-spectrum efficacy with formaldehyde-free protection.

Key advantages of SURFSHIELD LS

- Formaldehyde-free, MIT-free, CIT-free → Fully compliant with tightening global regulations.

- Broad-spectrum in-can protection → Strong activity against bacteria, yeast, and mold.

- Stable and versatile → Works reliably across coatings, adhesives, emulsions, and dispersions.

- Temperature and pH stable → Consistent performance under varying conditions.

- Low viscosity → Easy handling and formulation integration.

- Free of toxic heavy chemicals → Safer for formulators and end-users.

- Cost-effective → Reliable preservation at low use levels.

- Scalable supply → Available in packaging suitable for R&D and full production.

By choosing SURFSHIELD LS, formulators gain a preservative that is not only safe and compliant but also robust enough to handle today’s toughest microbial challenges.

Take the Next Step: Partner with a In-Can Preservative Biocide Supplier

In today’s competitive environment, selecting the right coating preservative supplier is as important as selecting the right preservative itself. Maha, as a wet state preservatives supplier, goes beyond supply — offering technical guidance, formulation insights, and sample support to help you integrate SURFSHIELD LS effectively.

📩 Contact Maha today to request a free sample of SURFSHIELD LS and learn how this innovative preservative can safeguard your water-based formulations.