Environmental issues are still of great concerns as our consumption for household are increasing. As we could hardly control the usage and the amount of waste produced by household products, we can reduce or replace the harmful chemicals found in these products! Until now, most of us still rely on shampoo and other cleansing agents that contained sodium laureth sulfate. Sulfate products are very effective in cleaning but is infamous for Skin Irritation and not Eco-friendly! So, how can we go green and at the same time without losing the efficacies of the products? APG and AEG surfactants replaced laureth sulfate with natural ingredients and have comparable efficacies as sulfate products! Recently, our supplier was awarded with top 100 Sub-Listed Enterprises of China Light Industry in the 7th comprehensive evaluation! We are also Eco-Certified and comply with REACH standards in production of chemical substances for our ingredients! Alkyl polyglycosides (APGs) are a class of non-ionic surfactants that are widely used in household, and industrial applications. Alkyl poly glucoside is made from natural fatty alcohols and glucose derived from renewable plants. The raw materials are usually Starch and Fat, and the end products are complex mixtures of compounds with sugars comprising hydrophilic end and alkyl groups with hydrophobic end. APGs uses natural ingredients (Starch, coconut oil/palm, etc.) which are more eco-friendly. Additionally, it is highly soluble in concentrated alkaline solution and in other electrolyte to make cleaning more effective. Also, APGs has good compatibility with various anionic and non-ionic surfactants which produces rich and stable foam. This enhances the efficacy of formulation and improve mildness. Most importantly, APGs is non-toxic and biodegradable with strong detergency properties! APGs is usually used in body wash, shampoo, facial wash, hand sanitizer, dish washing and cleaner for fruits and vegetables.

Items

|

Foam Height

| Foam Height | Foam Height |

Alkaline resistance

|

Wetting Property

|

Surface Tension

|

CMC

|

30s

|

3min

|

5min

|

NaOH

|

(DW)

|

mN/m

|

mg/L

| |

WQ810C

|

540

|

490

|

440

|

640

|

2.3S

|

26.2

|

823.8

|

WQ1200LG

|

440

|

420

|

405

|

–

|

13.2S

|

27.1

|

33.5

|

WQ2000D

|

530

|

510

|

500

|

590

|

5.2S

|

27.1

| 40.9 |

WQ810C

|

WQ2000D

|

WQ1200LG

|

Carbon Chain: C8~C10

|

Carbon Chain: C8~C14

|

Carbon Chain: C12~C14

|

Lower carbon chain-> Better penetration

|

Mixture of WQ 810C + WQ2000D

|

–

|

Least Mild

|

Milder than WQ810C, more stable and rich foam

|

Milder than WQ810C, more stable and rich foam

|

Homecare/house hold cleaning, hard surface cleaning

|

Shampoo, body wash and facial cleanser, Baby product cleanser

| Baby care, feminine wash |

Test Description

|

Specification

|

Detection Method

|

Appearance @ 25℃

|

Colorless or slight yellow transparent liquid

|

Visual Inspection

|

APHA Hazen

|

≤100

|

GB / T19464-2014

|

pH Value

|

11.5-12.5

|

GB / T19464-2014

|

Solid Content %

|

≥50.0

|

GB / T19464-2014

|

Ash Content %

|

≤3.0

|

GB / T19464-2014

|

Residual Alcohol Content %

|

≤1.0

| GB / T19464-2014 |

AEG is the improved version of APG. It contains additional polyoxyethylene chain between the alkyl chain and polyglycosides group. AEG has high tolerability to hard water (mineral water), solution in water at even at low temperature and high compatibility with other substances. Additionally, AEG surfactant is biodegradable and able to remove oily dirt with improved viscosity. Non-dioxane detected when tested. AEG is more suitable for liquid laundry detergent, dish washing, household cleaner, hard surface cleaning and as scouring agent in textile industry.

AEG 050

|

AEG 300

|

AEG 500

| |

Chemical Constitution

|

C12-14-(EO)3-Glucose 1.5

|

C12-14-(EO)3-Glucose 1.5

|

C12-14-(EO)3-Glucose 1.5

|

Content %

|

50.0%

|

50.0%

|

50.0%

|

Surface Tension @ CMC (mN/m,20℃)

|

27.5

|

28.5

|

29.3

|

CMC (ppm)

|

48

|

33

|

31 |

Ross Foam (0/5 min, 0.2%wt.aq.soln.,ac.)

|

64/58

|

67/62

|

75/65

|

Wetting Property

|

31.0

|

27.1

|

32.1

|

Flow Point(℃)

|

>5

|

>5

| >5

|

Cloud Point(℃) |

56

|

77

|

71

|

AEG 050

|

AEG 300

|

AEG 500

|

Mildest

|

Outstanding performance in solubilizing, emulsifying and thickening

|

Outstanding performance in thickening and water solubility

|

Moderate and stable foam

|

–

|

Strong resistance to hard water

|

Excellent Wetting Permeability

|

Excellent foam stabilizing

|

Excellent cleaning power

|

Good for Fabric Cleaning

|

Good for dish washing

|

– |

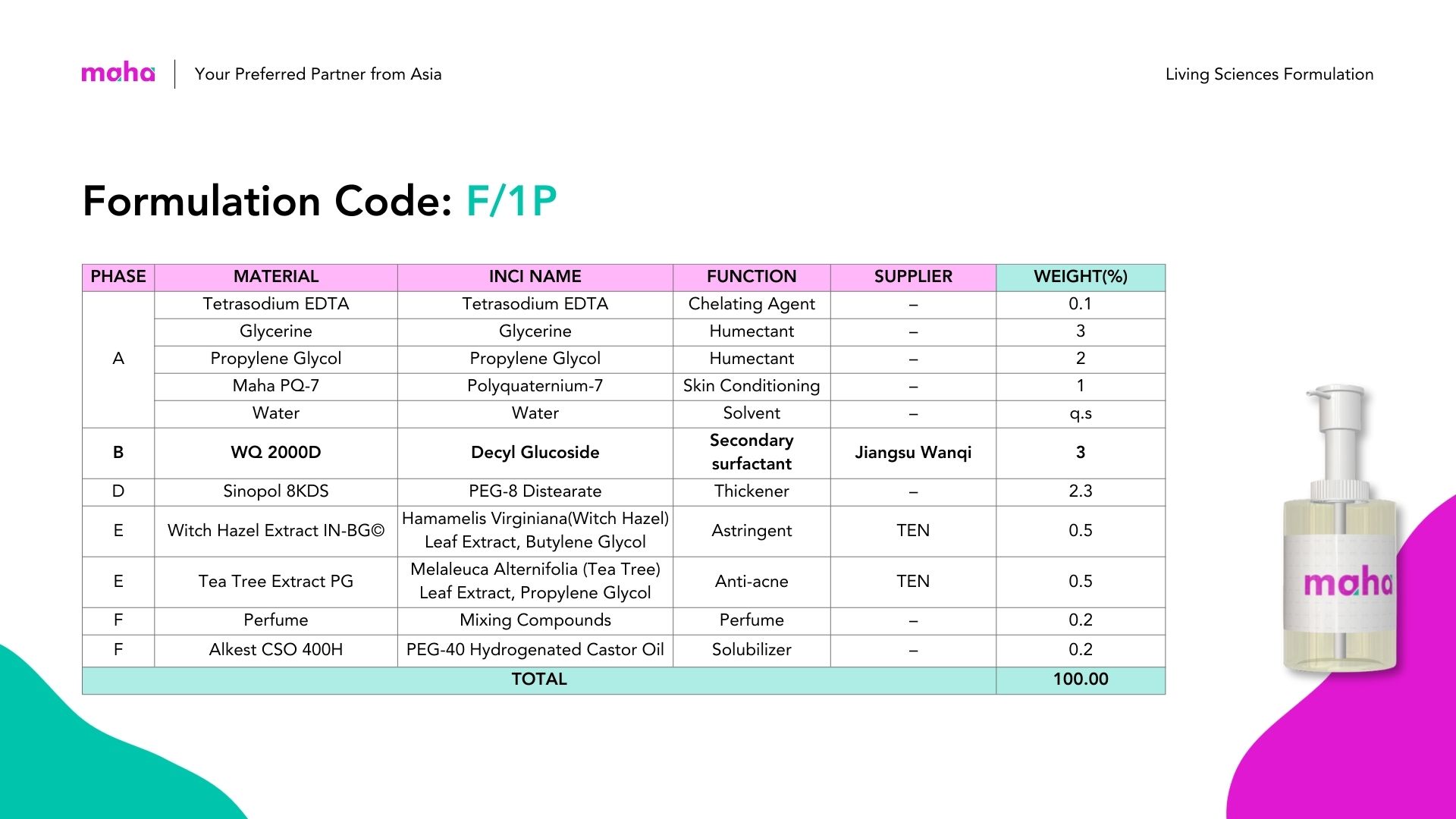

- Pre disperse phase A then mixing and heating at 70 ° C

- Add phase B to no.1, mixing and heating at 70 ° C

- Add phase C to no.2, mixing and heating at 70 ° C until back to clear appearance

- Decrease the temperature to 60 ° C, then add phase D, mixing while heating until dissolve

- Decrease the temperature to 45 ° C, then add phase E, mixing while heating

- Pre-disperse phase F at room temperature, then add to no.5, continue mixing

- Add phase G, then mixing again

- Adjust the pH with citric acid solution until in range 5.8 – 6.5

Final Products Appearance |

F/1P

|

Appearance

|

Viscous Liquid

|

Odor |

Specific Herbasolve

|

Color

|

Clear

|

pH

|

5.8–6.5

|

Viscosity, cps

|

1000 – 3000cps

|

- Mixing Tetrasodium EDTA and glycerin with water, and heating in 60 °C (phase B)

- Add Neoquta 3000KC into bulk no.1, mix and heat until homogenous, keep the temperature at 60 °C

- Add phase A step by step, WQ 1200 LG, Eversoft UCS-50SG then Cocamidopropyl Betaine, then mix until homogenous

- Add phase C, mix until homogenous and Rewopal was dissolved

- Decrease the temperature in 40o-50oC, then add phase D step by step, mix until homogenous

- Pre-disperse phase E at room temperature, then add to bulk no.5, then mix until homogenous

- Cooling the bulk, then adjust the pH in range 5.5 – 6.5

Final Products Appearance |

F/1L |

Appearance

|

Clear Liquid |

Odor |

Specific |

Color

|

Clear

|

pH

|

5.5–6.5

|

Viscosity, cps

|

cps: 1500 – 3000,@spindle 3, 18rpm |

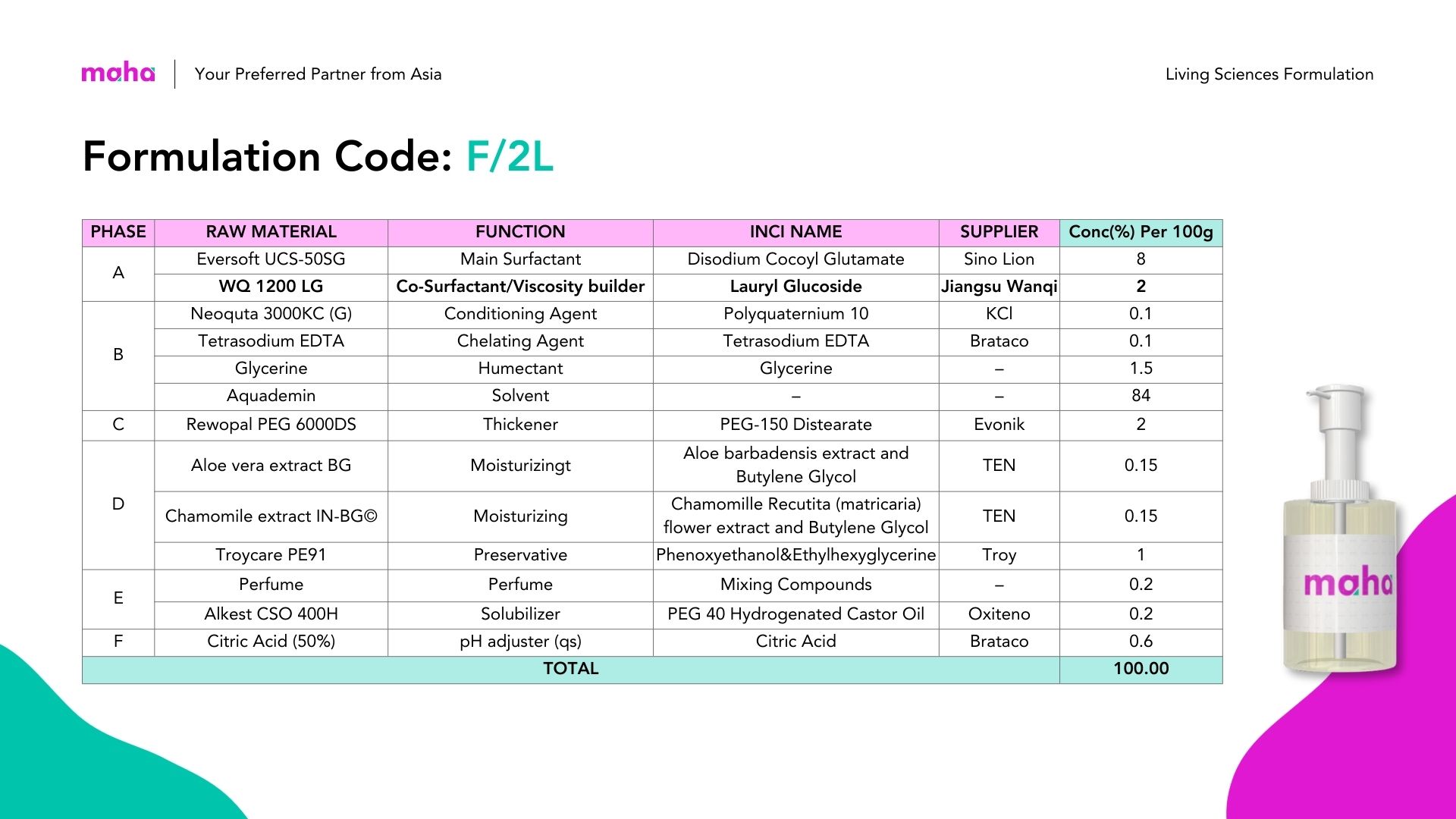

- Mixing Tetrasodium EDTA and glycerin with water, and heating in 60 °C (phase B)

- Add Neoquta 3000KC into bulk no.1, mix and heat until homogenous, keep the temperature at 60 °C

- Add phase A step by step, WQ 1200 LG, Eversoft UCS-50SG then Cocamidopropyl Betaine, then mix until homogenous

- Add phase C, mix until homogenous and Rewopal was dissolved

- Decrease the temperature in 40o-50oC, then add phase D step by step, mix until homogenous

- Pre-disperse phase E at room temperature, then add to bulk no.5, then mix until homogenous

- Cooling the bulk, then adjust the pH in range 5.5 – 6.5

Final Products Appearance |

F/2L |

Appearance

|

Clear Liquid |

Odor |

Specific |

Color

|

Clear

|

pH

|

5.5–6.5

|

Viscosity, cps

|

cps: 1500 – 3000,@spindle 3, 18rpm |

Our Solution

Let’s go green and protect our skins

without sacrificing the effectiveness of the products!

Contact us by clicking the link!