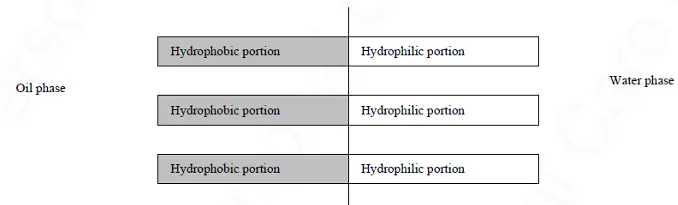

Choosing the right emulsifier for your formulation can be difficult. In an ideal emulsion, the emulsifier is equally attracted to the water phase and the oil phase. If the balance is tipped in either direction, the emulsifier may lose contact with the phase to which it is less attracted, causing the emulsion to break down. Furthermore, it requires trial and errors to get a stable formulation. Emulsifiers do more than ensure stability; they also affect the feel, texture, and properties of an emulsion. It’s therefore important to be well-informed about your options and the effects they will have.

How Emulsions and Emulsifiers Works?

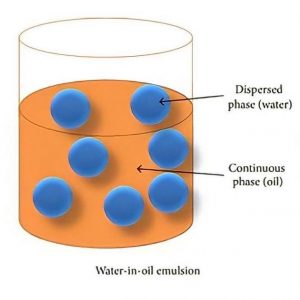

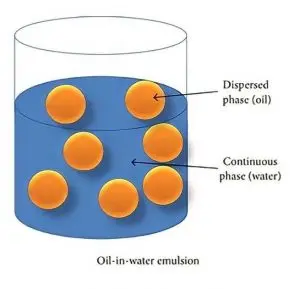

Emulsions are systems composed of two or more immiscible materials, in which one material (the discontinuous or internal phase) is suspended or dispersed throughout another material (the continuous or external phase) in separate droplets. The immiscible phases can be water, oil or silicone.

Emulsifiers are used in creams and lotions to mix water with oils. Since water and oil do not mix but stay separated, an additional agent (emulsifier) is necessary to form a homogenous mixture keeping water and oil together. There are 2 types of emulsifiers. Oil-in-water (o/w) emulsifiers keep oil drops packed in water, while water-in-oil (w/o) emulsifiers keep water drops packed in oil.

Tips In Selecting The Right Emulsifier!

1. Identify The Type Of Emulsion

a. Oil In Water (O/W) Emulsions

- Oil droplets are dispersed throughout a continuous water phase

- Creamy texture but do not feel greasy

- Coloured by water soluble dyes

- High electrical conductivities : pH can be measured

- Mix readily with water soluble liquids

b. Water In Oil (W/O) Emulsions

- Water droplets are dispersed throughout a continuous oil phase

- Tend to be greasy except when silicones are used

- Coloured by oil soluble dyes

- Low electrical conductivities : pH can’t be measured

- Mix readily with hydrophobic liquids

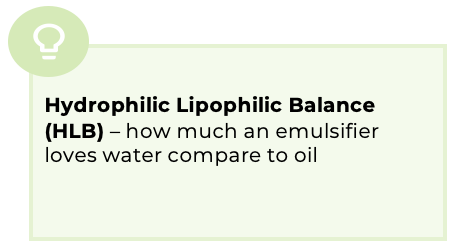

2. Choose Suitable HLB Value

HLB system is used to identify the chemical nature of emulsifiers and the type of emulsion formed.

|

|

| |||||||||

|

|

| |||||||||

|

| Emulri 6GP (Polyglycerol-6 Palmitate) HLB value: 10.5 | |||||||||

|

Solubilizer

|

|

3. Check pH and Charge Compatibility

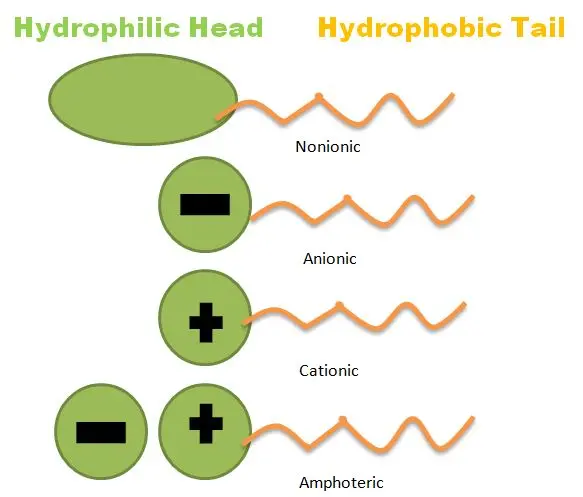

Types of emulsifiers based on charge:

I. Ionic Emulsifier

- Charged; Forms o/w emulsion by electric repulsion

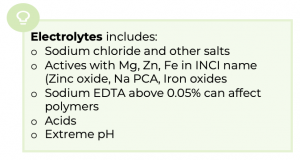

- Affected by excess charge, extreme pH and electrolytes

- Crystallises at freezing point temperature.

- Two types:

a. Anionic Emulsifiers

- Negative charge

- Not compatible with cationic environment

- Example: Stearic acid, sodium stearoyl glutamate, glyceryl stearate

b. Cationic Emulsifiers

- Positive charge

- Not compatible with anionic environment ; used for conditioners

- Example: Cetrimonium chloride, Behentrimonium Chloride

II. Non-ionic Emulsifiers

- No charge; Forms o/w or w/o emulsion by physical barrier

- Not affected by charge or electrolytes

- compatible with both cationic and anionic emulsifiers

- Reduces viscosity and stabilization effect at warm to hot climates

- Example: Cetearyl alcohol, Stearyl Alcohol, Ceteareth-20

4. Check Product Form and Marketing Concerns

Product Type | Recommended Emulsifier Inputs | |||

|

| |||

|

| |||

| Crème cleanser (o/w) |

| |||

Lotion/Cream/Body Butter (o/w) | •Anionic high HLB waxy emulsifier (if no compatibility issues): mid-point of recommended dose •Non-ionic waxy high HLB emulsifier blend: use high side of recommended dose •Add 2-3% low HLB waxy emulsifier to build viscosity and reduce soaping effect •Use water compatible polymer/gum to stabilize and build viscosity | |||

Conditioner |

| |||

| •Low HLB waxy emulsifier as primary emulsifier •Low HLB waxy or low liquid emulsifier blend as secondary emulsifier •Add oil compatible polymer •Add NacL or Magnesium sulfate hepta hydrate to water phase to give water charge •Do not use chelating agents. |

*According to George Deckner of UL Prospector

Want to know more about our solutions? We offer great quality emulsifiers from Ecoori Emulri Series!