In today’s competitive market, cost optimization is a key consideration for manufacturers across industries. TPGDA (Tripropylene Glycol Diacrylate) and TMPTA (Trimethylolpropane Triacrylate) are two widely used monomers in the coatings industry, particularly in UV-curable formulations. TPGDA is a diacrylate ester of tripropylene glycol, while TMPTA is a triacrylate ester of trimethylolpropane. These monomers play a crucial role in the formulation of UV-curable coatings, where they serve as crosslinking agents, imparting properties such as rapid curing, high crosslink density, and excellent adhesion to various substrates.

Furthermore, their high cost relative to other raw materials poses challenges for manufacturers seeking to optimize production expenses without compromising on quality or performance.

Introducing Solvacoat Oligomer UV Resin

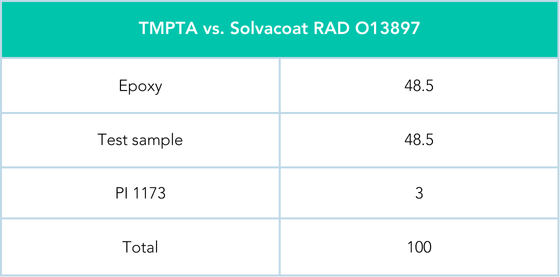

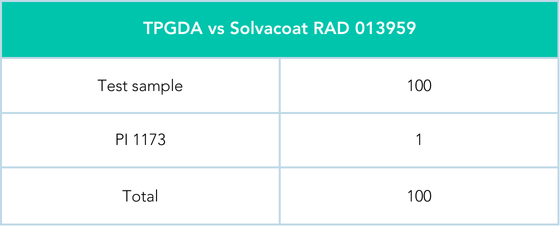

Given the considerations from those two monomers, Solvacoat has developed an innovative oligomer that serves as a 1:1 replacement for TPGDA and TMPTA. With simple formulation, Solvacoat RAD 013897 can be an alternative formula for non-TMPTA content and RAD 013897 is also less irritant than TMPTA. In other hand, we also have alternative formula for TPGDA which is Solvacoat RAD 013959 that can reduce gloss point, suitable for matte or low gloss formulation.

These oligomers offer comparable performance to their monomeric counterparts while mitigating the health and safety risks associated with TMPTA. Additionally, they provide cost savings for manufacturers without sacrificing quality or performance, making them an attractive alternative for UV-curable coatings formulations.

Key Advantages of Solvacoat UV Resin

Key advantages of Solvacoat RAD 013897 and Solvacoat RAS 013959 are:

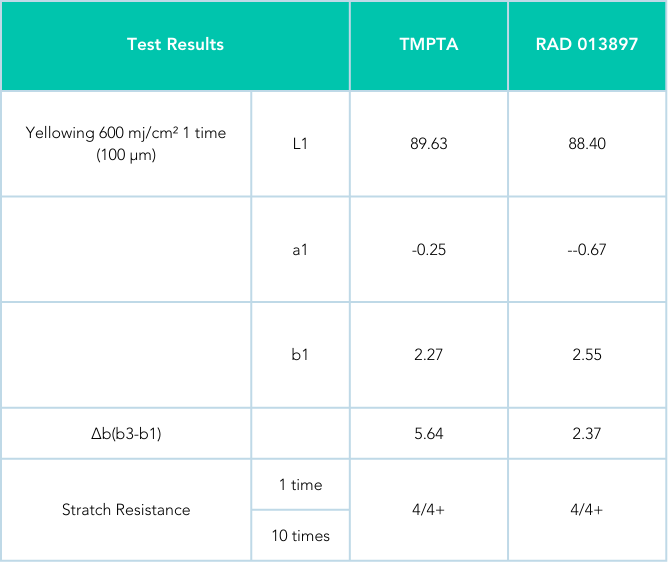

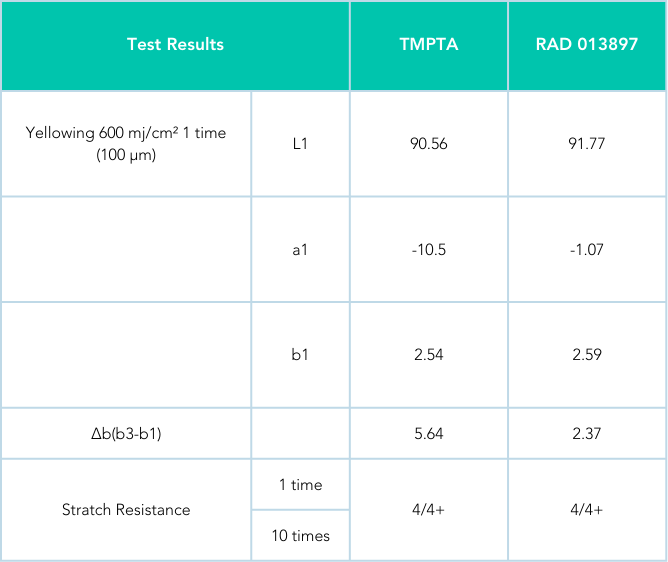

- Better Yellowing Resistance

Solvacoat UV resins demonstrate enhanced resistance to yellowing over time compared to standard UV monomers. The unique chemical structure of Solvacoat resins results in greater stability and reduced color shift upon exposure to heat and light. - Cost-downSolvacoat UV resins are offered at a lower price point than traditional monomers. By substituting TMPTA or TPGDA in your formulation, you can slash overall costs by up to 18%, optimizing your budget without compromising on quality.

- Mild on Skin

Unlike TMPTA and TPGDA, our products are non-irritating, ensuring a safer working environment for you and your team.

Comparison of Solvacoat and Monomer UV

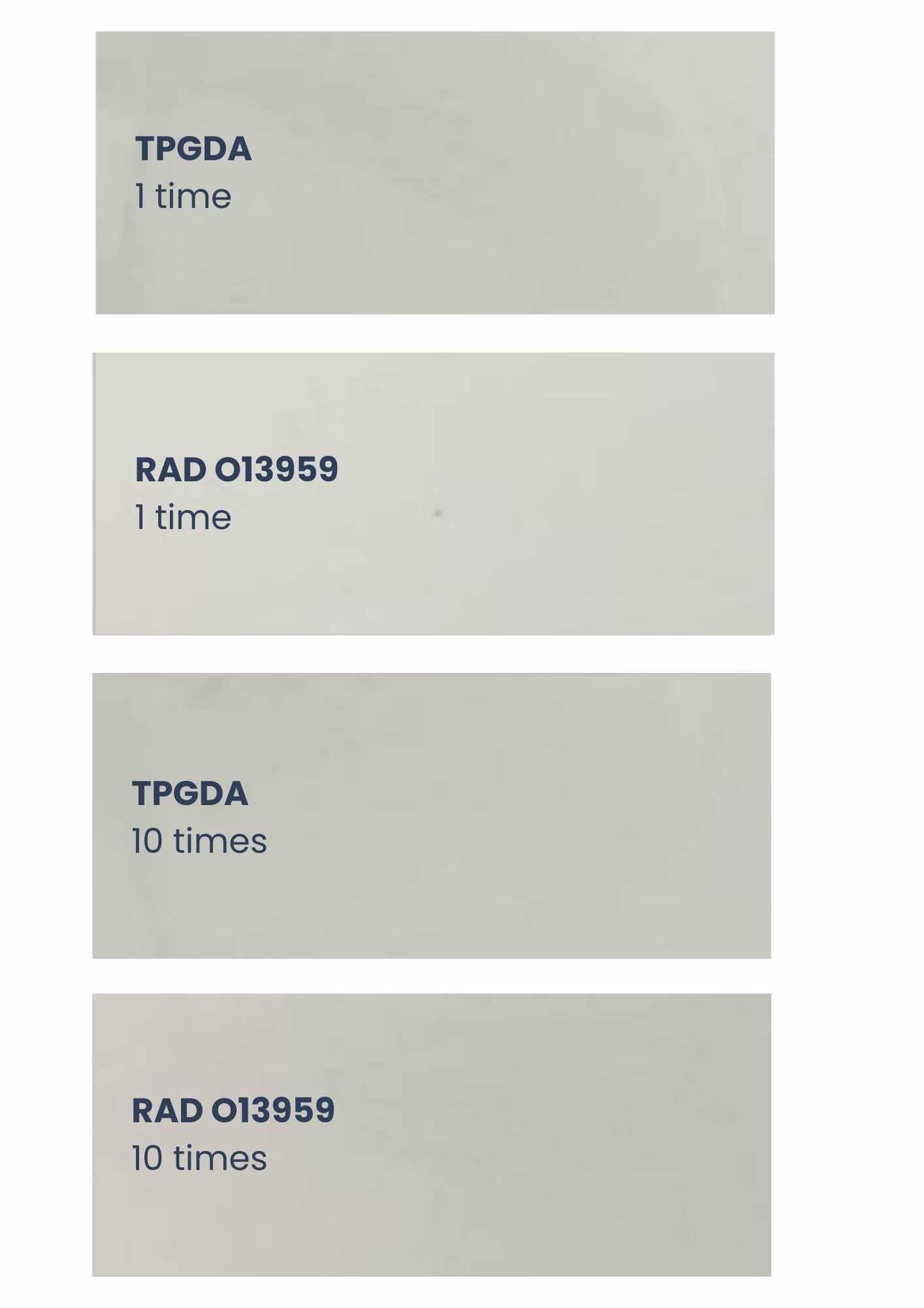

We conducted a Test between both TMPTA and TPGDA and our Solvacoat UV products.

TPMPTA vs Solvacoat RAD 013897

TPGDA vs Solvacoat RAD 013959

Potential Applications of Solvacoat UV Resin

OPV Coating

Wood Coating

Plastic Coating

Solvacoat UV Resin as a cost-effective replacement of TMPTA and TPGDA

Solvacoat RAD O13897 and Solvacoat RAD O13959 are suitable for 1:1 replacement for OPV and wood coating. For other applications, they can replace more than 80% of TMPTA or TPGDA in a formulation.

Maha Asia is an official distributor for Solvacoat UV Resin replacement of UV monomer, contact us for more information.

Looking for cost-effective substitution for your UV monomer?