The demand for high-performance anticorrosion coatings has never been greater. With increasing pressure to meet VOC regulations and rising customer expectations for durability, formulators are seeking advanced solutions that deliver strong corrosion resistance, substrate adhesion, and long-term stability, all while maintaining environmental compliance and processing efficiency.

This is where ASCONIUM®, a range of liquid anticorrosion additives from ASCOTEC, offers a breakthrough alternative to conventional pigment-based systems. Designed for both water-based and solventborne metal coatings, ASCONIUM® helps manufacturers achieve superior performance with fewer raw materials, reduced zinc content, and broader substrate compatibility.

Tackling the New Challenges in Corrosion Protection

Traditional anticorrosion coatings have long relied on heavy metal-based pigments, such as zinc phosphate, to inhibit rust formation. However, evolving global regulations and the push for more eco-conscious formulations have made these systems increasingly difficult to justify, both technically and economically.

Meeting targets like early water resistance, film integrity, and multi-substrate adhesion has also become more difficult as resin systems shift toward low-VOC and waterborne technologies. Many coatings today show premature blistering, poor adhesion on non-ferrous metals, or a lack of long-term resistance under salt spray or humidity exposure.

Discover Opportunities with Maha - Your Trusted Partner from Asia

What Makes ASCONIUM® Different?

Unlike conventional powder-form inhibitors, ASCONIUM® is a liquid organic additive that can be easily incorporated into clear or pigmented formulations. It delivers enhanced protection through four key mechanisms:

Enhancing water resistance of the coating

Improving adhesion between the coating and the substrate

Reinforcing the film structure for better durability

Adsorbing onto the metal surface to form a protective anticorrosion layer

These mechanisms work together to strengthen both the coating and its bond to the substrate, helping coatings maintain their performance in aggressive environments. ASCONIUM® is effective on ferrous and non-ferrous substrates, including cold-rolled steel (CRS), aluminum, zinc alloys, and copper.

Proven Performance in Industry Testing

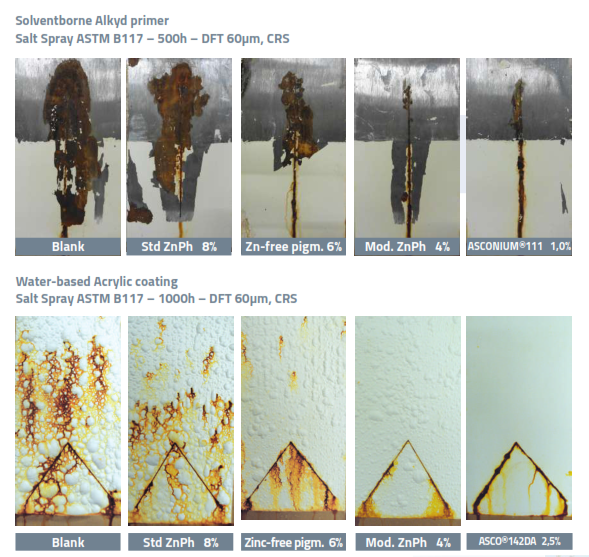

ASCONIUM® has demonstrated strong performance in industry-standard tests across a variety of systems and conditions.

In salt spray tests (ASTM B117 and ISO 9227), ASCONIUM® achieved over 1000 hours of protection in water-based acrylic coatings at 60 µm dry film thickness. These results were better than standard zinc phosphate systems, even at lower dosages. In humidity testing (ISO 6270), films with ASCONIUM® showed superior blister resistance and better adhesion retention than control samples.

Adhesion tests (ISO 2409) confirmed reliable performance after 250 hours of salt spray or 120 hours of humidity exposure. Even at a usage level of 1 to 2%, ASCONIUM® maintained film integrity without affecting gloss, clarity, or formulation stability. This makes it suitable for both pigmented and clear coatings.

Versatile Across Resins and Coating Systems

One of ASCONIUM®’s key advantages is its compatibility with nearly all major binder systems used in today’s industrial and architectural coatings. It can be applied in:

Water-based acrylics, PUDs, and alkyds

Solventborne alkyds, 2K PU, 2K epoxy, and polyesters

Clear and high-gloss systems where appearance must not be compromised

A recent innovation, ASCONIUM®-500, is designed for VOC-free water-based DTM coatings and delivers excellent results at only 1% loading. It enables coatings to achieve corrosion classifications up to C5 Medium, based on ISO 12944, with a single coat.

Sustainable and Application-Friendly

ASCONIUM® is designed to meet both environmental and operational demands in modern coating formulations. Its unique liquid format, combined with high-performance functionality, delivers clear advantages for formulators seeking efficiency, durability, and regulatory compliance.

Key advantages include:

- Eco-compliant formulation: Free from heavy metals, VOCs, and tannic acid derivatives

- Simplified processing: Liquid form allows easy handling, fast dispersion, and no need for high-shear mixing or pH control

- Improved durability: Boosts water and humidity resistance, extending coating life while reducing blistering and underfilm corrosion

- Wide application scope: Ideal for clear coatings and multi-metal systems where both appearance and protection are essential

Official Supplier of ASCOTEC's anticorrosion

As the industry moves toward more sustainable and efficient solutions, ASCONIUM® represents the future of anticorrosion additive technology. Whether you are developing a new DTM primer or enhancing a high-performance topcoat, ASCONIUM® can help streamline your formulation while improving long-term durability.

As the official supplier of ASCOTEC’s anticorrosion additives in Vietnam, Maha Asia is ready to support your goals. Our team offers technical assistance, product recommendations, and formulation support tailored to your application needs.