In the chemical and materials concept, the dispersion process is an event of distribution of a material or substance in the phase or medium of another material. The phases of the dispersed and dispersing substance in this case can be in the same phase or different phases. For example, perfect dispersion of a solid in a liquid will result in a solution.

In its application in the coating industry, dispersing agents are commonly used to assist the dispersion process of a substance into its dispersing medium. Dispersing agents (dispersants) can help the dispersion process by lowering the surface tension in a medium to increase the solubility of the dispersed substance

Introducing Coadis 123K:

A hydrophobic Dispersing Agent

COADIS 123K is a synthetic, versatile dispersant that provides easy fillers and pigments dispersion, good storage stability, and improved water resistance to water-borne systems. It is recommended for flat or gloss dispersion paints, renderings and plasters, and also organic pigment pastes (e.g. carbon black dispersion). Its utilization contributes to avoiding flotation and foam generation and provides excellent color acceptance.

Coadis 123K Key Features & Characteristics

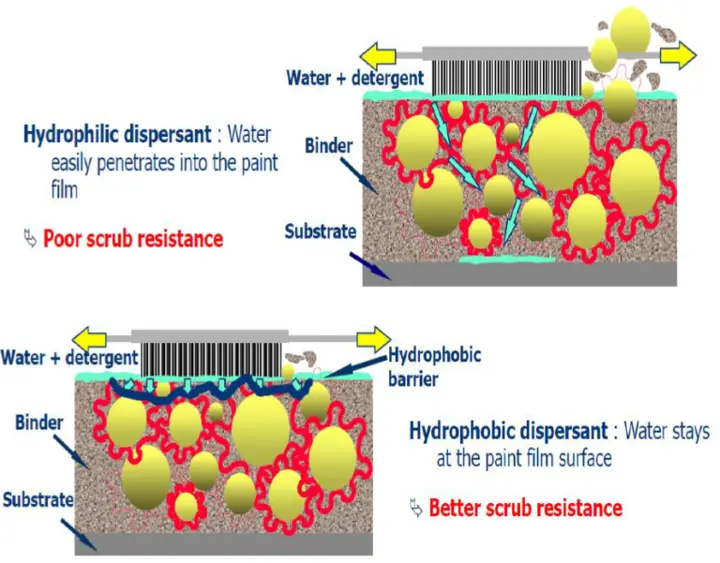

With its hydrophobic character, Coadis 123K significantly contributes to improving the water resistance of water-based systems with high PVC, such as plasters, renderings, and flat dispersion paints, compared with classical acrylic dispersants. Water resistance can be estimated, e.g. for flat dispersion paints, through wet scrub resistance tests on dry film or early water resistance tests on recent film.

Replacement of a classical acrylic dispersant by Coadis 123K in a washable flat dispersion paint can raise the water resistance of the paint up to a scrub resistance level.

Image 1. Key features of Coadis 123K

Image 1. Key features of Coadis 123K

Coadis 123K Key Benefits

Coadis 123K requires levels of use between 0.1% and 1% (dry product on total formulation weight) and more often between 0.1% and 0.5% (e.g. in renderings, in flat and gloss dispersion paints). Levels of use are higher for the formulation of organic pigment pastes and can reach until 15% for a carbon black dispersion (dry product on pigment weight).

This product should be added preferably before pigment introduction in order to reach the best dispersing efficiency, but can also be introduced at each step of the formulation if needed.

Image 2. Early water resistance of Coadis 123K

Image 2. Early water resistance of Coadis 123K

Improved Paint Properties Observed Using Coadis 123K

Other properties observed that are improved using Coadis 123K are:

- Acid rain resistance for 60% PVC exterior wall paint

- Alkali burnout, and salt resistance for exterior primer

- Surfactant leaching test as per ASTM D-7190 to help water marks

- Paint film water absorption

Coadis 123K

Available in Indonesia, Thailand, Cambodia, and Sri Lanka.

Get more information by contacting us via email sales@maha.asia

Excited to Learn More Solutions?

We offer a wide range of ingredients for surface technology formulations.

Consult with our technical experts to find your perfect solution!