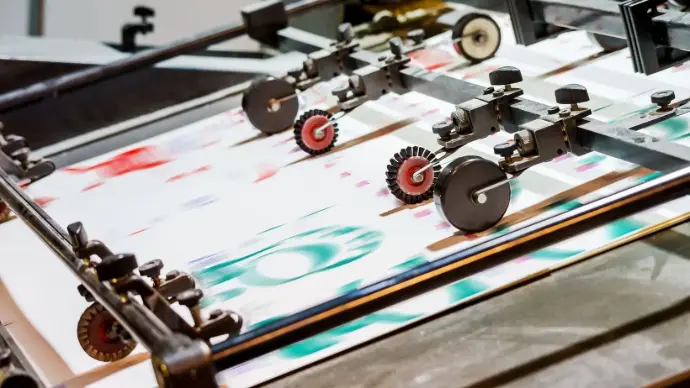

Paper varnishes play a crucial role in enhancing the aesthetics and functionality of paper products. They offer protection against scratches, moisture, and wear, while also improving printability and visual appeal. In recent years, UV-curable (UV) oligomers, particularly epoxy acrylate oligomers, have emerged as a promising alternative to traditional paper varnishes. In this article, we will talk about how epoxy acrylate oligomer from Solvacoat, RAD 532F, can improve UV OPV formulation.

What is Epoxy Acrylate Oligomers

Epoxy acrylate oligomers are a type of reactive resin, combining the beneficial properties of both epoxy and acrylate chemistry. These oligomers are known for their excellent adhesion, high reactivity, and superior mechanical properties. They are widely used in UV-curable coatings, inks, and adhesives.

Solvacoat RAD 532F is an advanced UV oligomer product specifically designed for use in UV OPV formulations. It is a versatile epoxy acrylate oligomer that performs exceptionally well under both UV mercury lamps and UV LED lamps without requiring a change in the photo initiator type. Because its flexibility can make it a preferred choice for formulators who need a reliable and effecient solution for paper varnish applications.

Product Advantages of Solvacoat RAD 532F

High Gloss: This product imparts a high-gloss finish to paper, enhancing its visual appeal and making printed materials stand out.

BPA Free: Solvacoat RAD 532F is free from Bisphenol A (BPA), making it a safer and more environmentally friendly choice for consumers and manufacturers.

Good Yellowing Resistance: The oligomer exhibits excellent resistance to yellowing, ensuring that the varnish maintains its clarity and brightness over time.

Fast Curing Speed: It offers rapid curing under both UV mercury and UV LED lamps, increasing production efficiency and reducing operational costs.

Affordable Price: Solvacoat RAD 532F is competitively priced, providing high performance at an economical cost, making it an attractive option for various applications.

Comparison Solvacoat RAD 532F vs Product A

Comparison Analysis:

- Solvacoat RAD 532F (left) has a good yellow resistance with Thickness 10 micron, Gloss point 60 Degree can achieve more than 95 compared to Product A (right)

Epoxy Acrylate Oligomers for UV Overprint Varnish

The use of epoxy acrylate oligomers in UV overprint varnish for paper applications is a testament to the advancements in coating technologies. By combining the best properties of epoxy and acrylate chemistries, these oligomers provide a versatile and efficient solution for enhancing the quality and durability of printed paper products.

Solvacoat RAD 532F stands out as a top choice due to its flexibility in curing, high gloss, BPA-free formulation, and competitive pricing. As industries continue to seek ways to improve sustainability and efficiency, the role of epoxy acrylate oligomers in paper varnish applications is set to grow even more prominent.

Maha Asia is an official distributor of UV Oligomer for Paper Varnish in Indonesia, Singapore, Thailand, and Vietnam. Contact us for more information.

Looking for Alternative UV Oligomer Paper Varnish Formulations?

LET OUR TECHNICAL EXPERTS HELP YOU