What Is Elotex MP2050?

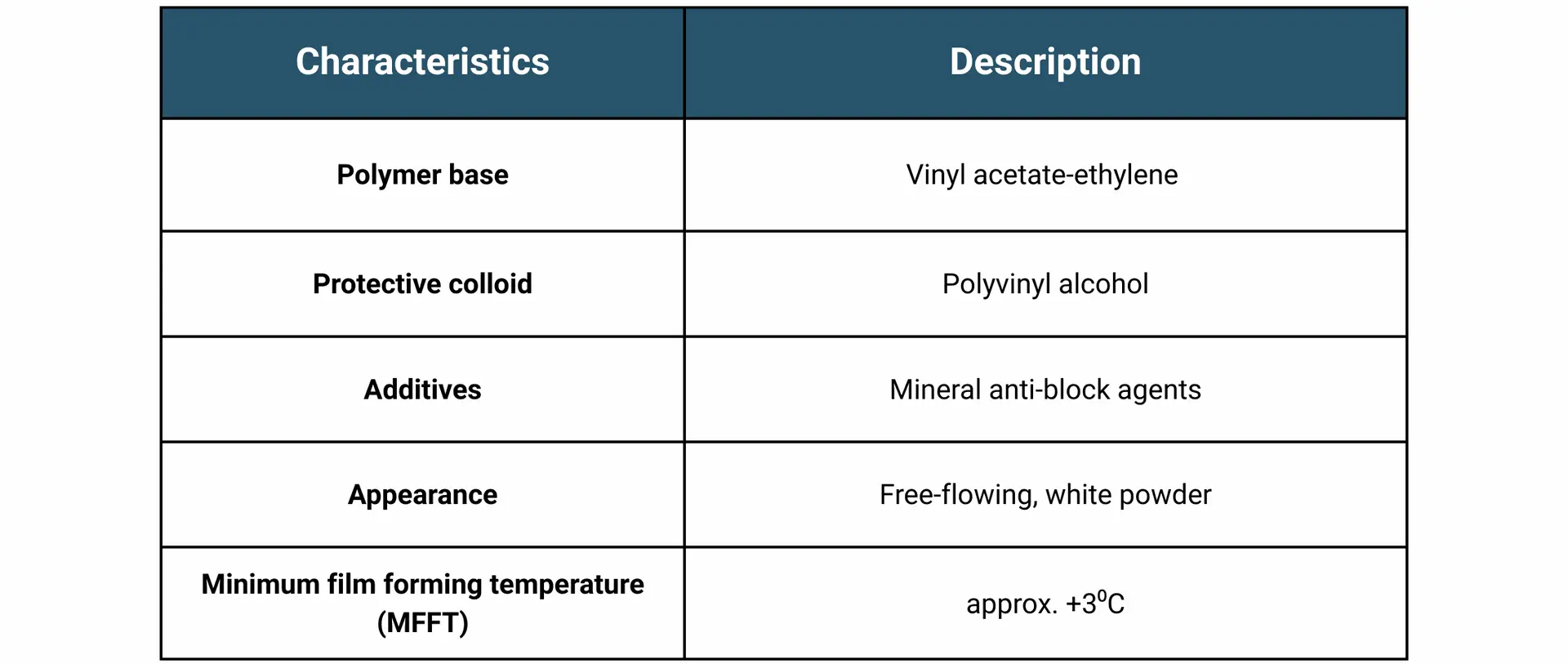

Elotex® MP2050 is a redispersible polymer powder (RDP) based on vinyl acetate–ethylene. Supplied as a free-flowing white powder, it contains polyvinyl alcohol as a protective colloid and mineral anti-block agents to ensure stability. With a minimum film-forming temperature (MFFT) of approximately +3 °C, Elotex MP2050 functions as an organic binder in a variety of dry mix formulations.

Unlike a simple mortar mixture of cement, sand, and water, mortars enhanced with Elotex benefit from improved strength, flexibility, and durability after curing. This makes Elotex a trusted choice for formulators who want more than just the basic mortar ingredients and are looking for modern performance additives.

Image 1. Elotex MP2050 Characteristics

How Elotex MP2050 Improves Polymer-Modified Mortars

When added to a dry mix, Elotex MP2050 redistributes during hydration, forming a strong polymer film throughout the mortar. This process improves both application properties and long-term durability.

Key performance benefits of Elotex MP2050

- Better workability – smoother and easier to apply.

- Higher adhesion and cohesion – acting as a reliable bonding agent for mortar.

- Greater deformability – flexibility reduces cracking under stress.

- Improved abrasion resistance – more durable in demanding applications.

- Eco-compliance – very low VOC emissions, aligning with sustainable building standards.

This is why Elotex MP2050 is widely used in polymer-modified mortars, transforming ordinary formulations into high-performance solutions. For professionals seeking to understand how to mix mortar with additives, Elotex represents the critical step forward.

By working as both a mortar bonding additive and an organic binder, Elotex MP2050 provides consistency that cement and sand alone cannot achieve.

Processing and Handling Guidelines for Elotex Redispersible Powder

To maximise performance, Elotex MP2050 should be processed and stored according to the Technical Data Sheet:

- Storage – keep in a cool, dry area at ≤25 °C, in original packaging.

- Shelf life – use within six months of delivery.

- Handling – avoid stacking pressure, heat, or moisture that may cause blocking.

- Mixing – blend with other dry additives before adding water. Keep mixing times short, as the powder has thermoplastic behaviour and excessive shear can damage performance.

Applications of Elotex MP2050 in Construction

Because of its versatility, Elotex MP2050 is used in a wide range of construction products, including:

- Tile adhesives (C1/C2, ISO 13007)

- Tile grouts (CG1/CG2, ISO 13007)

- Cement renders and gypsum plasters (base coats, skim coats, topcoats)

- Joint fillers and smoothing compounds

In all of these, Elotex functions not only as a bonding agent for mortar but also as the backbone of durable, flexible polymer-modified mortars that resist cracking and improve adhesion across substrates.

Finding a Trusted Elotex MP2050 Supplier

For manufacturers and contractors, sourcing from a reliable partner is just as important as choosing the right additive. As an official channel, Maha provides support as an Elotex MP2050 supplier. We go beyond distribution, offering:

- Technical guidance on formulations

- Application insights for specific construction needs

- FREE samples for development and testing

👉 If you’re ready to enhance your formulations with Elotex, Maha is your trusted partner.